Welcome to Anhui XinNing Equipment CO.,Ltd

Welcome to Anhui XinNing Equipment CO.,Ltd

Automatic Casting & Molding Line Equipment for Cast Ball Production adopts sand coated in metal mold cavity foundry technology,which is fit for producing high chrome casting balls

Automatic Casting Grinding Media Ball Molding Line

The automatic casting grinding Media ball molding line adopts a technology called sand coated in metal mold cavity, which is fit for producing high chrome casting balls. The whole casting ball molding line drives by hydraulic, pneumatic, and electric, and PLC automatic control. Two main control cabinets and five sub-control cabinets control the whole operation and mechanism of the casting ball molding line. In the two control boxes, equipped with PLC automatic control and touching screen. Operators can monitor the whole production process through the screen. When there is any problem, it can automatically alarm. All control cabinets are equipped with an emergency stop button. It also has the ability of remote maintenance & diagnose failure functions. Mainly need four workers to control the entire operation. One for molding, one for pouring, one for cleaning molten iron slag on the mold after pouring, one for checking if it is clean or not for used sand in the mold, not including auxiliary workers.

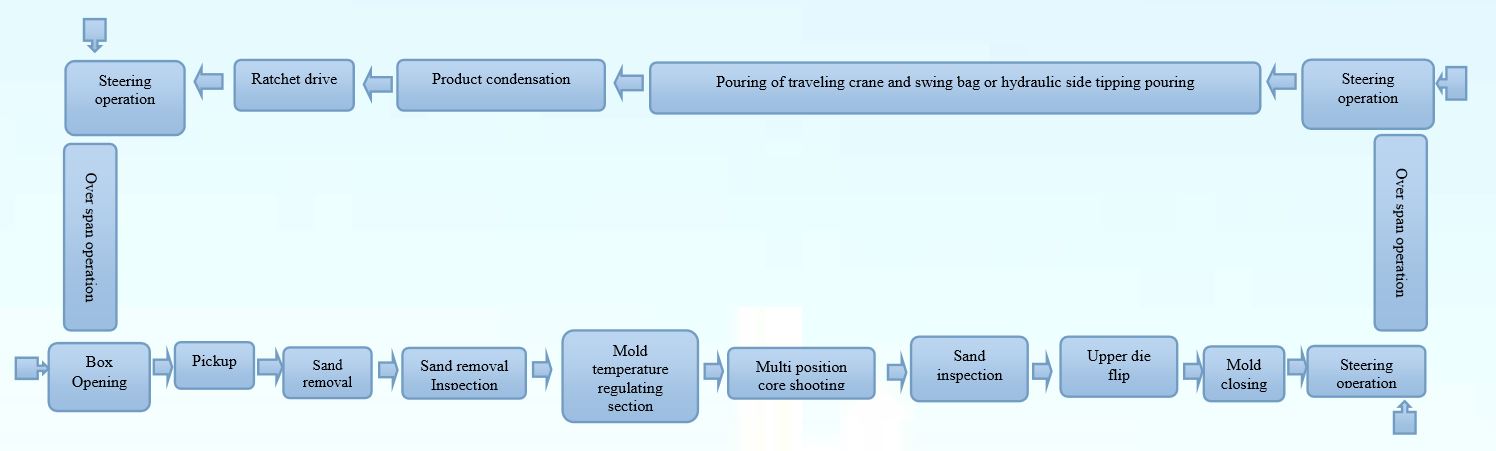

Automatic Casting Grinding Media Ball Molding Line Flow Chart

preheat iron mold ➨ ➨ ➨shoot sand to iron mold by core shooting machine ➨ ➨ ➨Checking iron mold with sand, adding and reduce sand if needed ➨ ➨ ➨ Pouring Molten metal ➨ ➨ ➨open the mold and grinding balls coming out ➨ ➨ ➨clean out the residual sand ➨ ➨ ➨molding again.

Casting products:

Foundry casting for high chrome casting steel ball automatically produces cast grinding balls; Grinding Mill Balls; Grinding Balls; Grinding Media, and crankshaft.

Casting Line Advantages:

(1) Alternating with a live and non-live roller, which makes the whole line operation smoothly. It can run normally even lacking mold

(2) Only 3-4 people to operate the whole line

(3) The molding line and pouring line realize the function of non-interfering,inter-supply, and hoarding, stabilize and speed up the space of real-load running.

(4) The fasted speed of pouring line 25″

(5) Four size ball mold can run at the same time

(6) Providing far distance service by wifi, when there is electric damage on the device, the user can alarm and the display screen can show the mistake reason solving method. The operator can call our service center, our company can solve the damage by website, highly improve the quality of after-sale service