Welcome to Anhui XinNing Equipment CO.,Ltd

Welcome to Anhui XinNing Equipment CO.,Ltd

1. Grinding ball production line is mainly used for the production of grinding ball matched with the ball&nbs...

1. Grinding ball production line is mainly used for the production of grinding ball matched with the ball grinding machine (widely applied to mine, cement and power generation industries). In past times, grinding ball production is manually produced. With the development of technology, now the automatic and intelligent production line has gradually replaced the traditional methods and has become the hot research direction to save energy, reduce consumption, reduce labor intensity, improve operating environment and control grinding ball quality.

2. Solved problems: On the basis of grinding ball production mechanization, automatic and intelligent technical upgrading is carried out. The main technical problems of the production line include:

In respect of the connection between single machine structure design and tie line, design and improve the safety of production control by virtue of systemic simulation technology.

solve the problems of poor operating environment, low production efficiency, high energy consumption, and quality instability, etc.

3. Function:

The output of the single machine, single production line, and a single shift is about as high as 5000 ton/ year.

The technological yield of grinding ball is about 76%.

4. Key technological and innovating points:

Double-station integrating sand-shooting technology is used to ensure the casting system and integrating the forming of product sand shooting.

The resonance cleaning mechanism is applied to achieve a high shake-out effect.

Automatic and intelligent mold temperature control is implemented, in accordance with technological mold pre-heating requirements different specifications of grinding balls.

Automatic and intelligent vertical insulating casting system technology is applied.

Integrated technology is applied to achieve automatic cleaning by metal mold assembling blowing and sending the used sand.

Main characteristics of XN-TF-90II (Horizontal Parting) High Chrome mill ball casting production line

1. It is applicable to the production of 40mm-150mm chromium forging ball and austempering ball product with the average machine-hour production capacity of about 2 tons/h.

2. Applied with ductile and open operational technology and principle, it has higher automaticity. There are four working stations in total and requiring five workers in a production line.

3. Casting method:casting with bottom constant-temperature casting machine or multi-point casting ladle.

4. The equipment possesses over ten patents, which mainly embodies in:

Double-station core shooter

Integrated riser molding

Automatic sand shakeout

Automatic purging and intelligent temperature control design (sand shooting mold temperature control of mold condensate case unpacker) and other patents and technological innovations.

5. The overall production line can be equipped with dust-collecting and smoke-extracting environmental protection devices to satisfy the working environment for modern enterprises.

High Chrome mill ball casting production line possesses many inventions and patent technologies:

1) Sand Lined Iron Mold Casting Line double-station synchronic sand shooting device, Patent No.: ZL201310645530.7

2) A kind of iron ball-casting mold, Patent No.: ZL201310176185.7

3) A riser molding and casting cavity integration mold, Patent No.: ZL201310278166.5

4) A riser molding and casting cavity integration mold, Patent No.: ZL201310278378.3

5) A riser molding and casting cavity integration mold, Patent No.: ZL201310299345.7

6) A riser molding and casting cavity integration mold, Patent No.: ZL201310298286.1

Relevant technical parameters of XN-TF-90II (Horizontal Parting)Sand Lined Iron Mold Casting Line

1) (Horizontal Parting)Sand Lined Iron Mold Casting Line model: XN-TF-90II;

2) Drive mode: pneumatic or hydraulic pressure;

3) Power supply/ voltage/rated power rate: 380V/50Hz; 75KW

4) The dimension of the production line: coverage of about 280 square meters.

5) Action mode: the action of the overall production line is intelligently controlled by PLC human-machine interface and synchronically, it can also be controlled by hand.

6) Required workers in a production line: 5-6 workers.

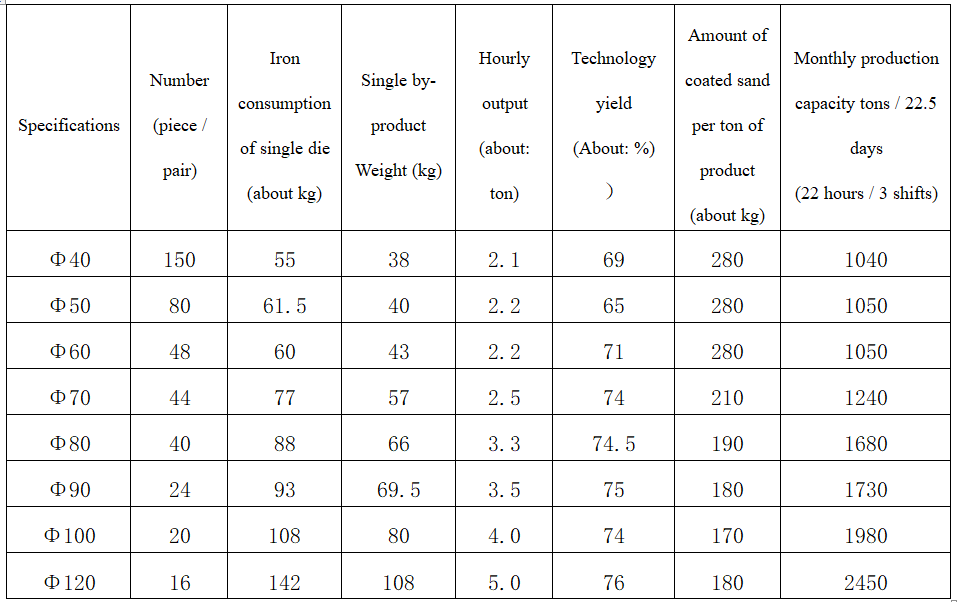

7) Operating rate: the no-load operating pace is about 40”; production pace: 60~80/ box (45~60 boxes per hour). For details, please refer to Schedule 1.

8) Annual output capacity per production line: 5000-12000 tons.

9) Applicable scope: production ofφ40~φ150 chromium forging balls, segments, CADI forging balls, and some small and medium-sized castings.

10) The standard configuration of mold: The configured mold for each specification is about 60 pairs.

11) The standard configuration of the template: 1 pair of the template (one piece of upper and one piece of the lower template) for each specification.

12) Configuration of shooter: 1 pair (one piece for upper and lower template respectively) for each specification.

13) Shooter cooling mode: running water circulating cooling;

List of rated production efficiency of high Chrome mill ball casting production line (under normal continuous casting conditions):

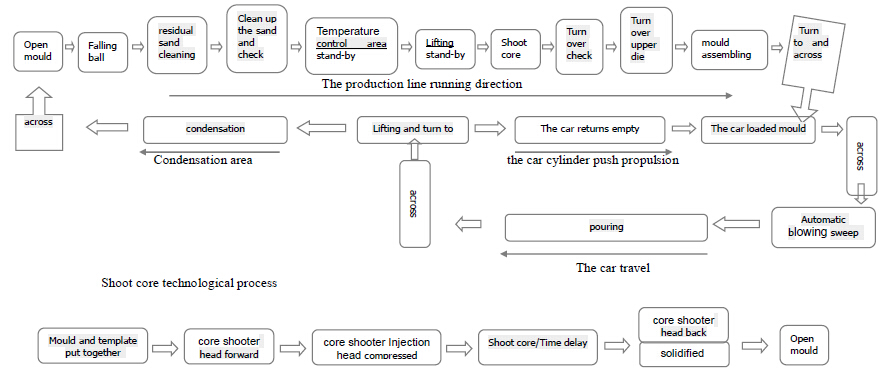

Production flow chart of XN-TF-90II (Horizontal Parting)Sand Lined Iron Mold Casting Line